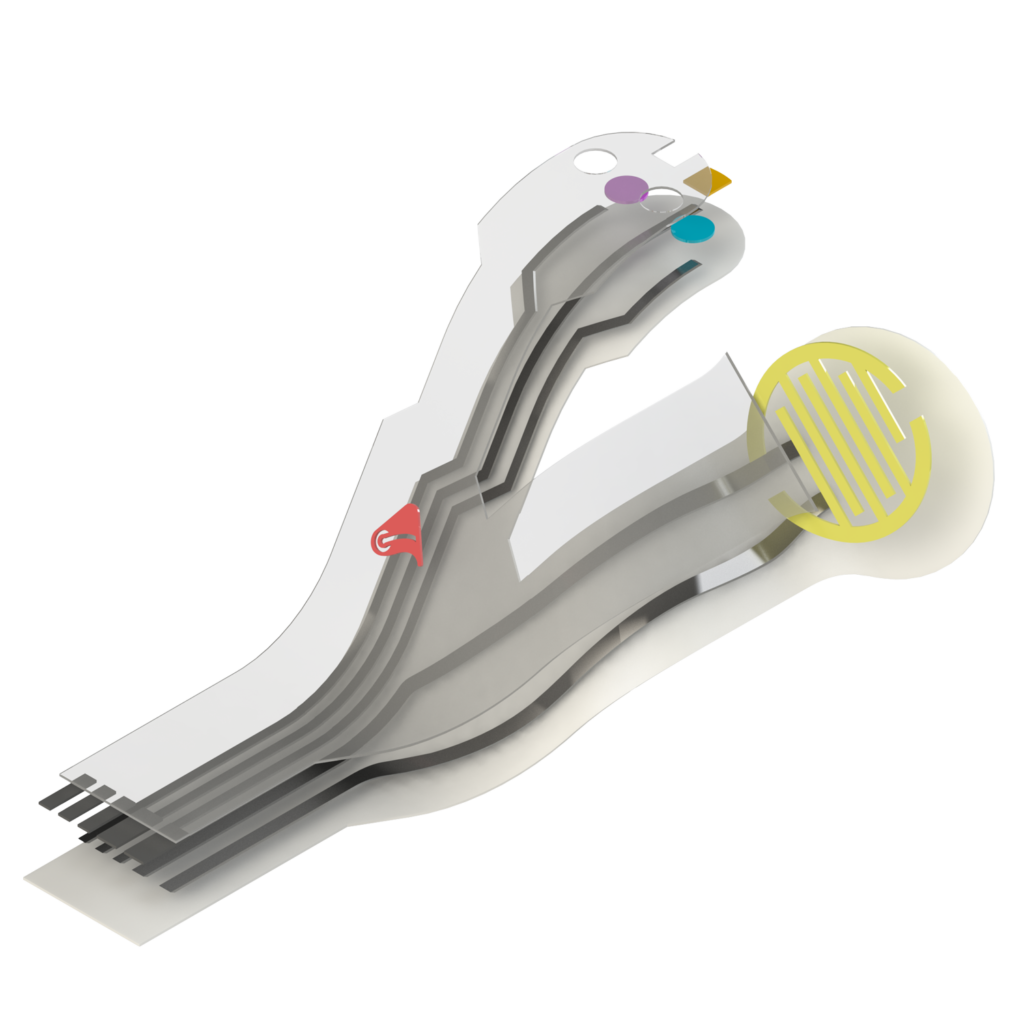

Puzzlen Sie sich ihren Wunschsensor. Egal ob Sie Ihre Anwendung in printed Electronic PCB oder FPC Technologie aufbauen, unsere SMD-Foliensensoren kleben Sie einfach auf das Ende der Leiterbahn und schon haben Sie ein Sensorsystem. Es ist kein weiterer Bearbeitungsprozess nötig, only – take it, stick it, use it.

Lassen Sie sich begeistern von unserem immer weiter wachsenden SMD-Foliensensor Portfolio.

Stripe-Foliensensoren können zusammen mit unserem Measurement Device sofort für Tests und Messungen verwendet werden. Auspacken, einstecken und losmessen.

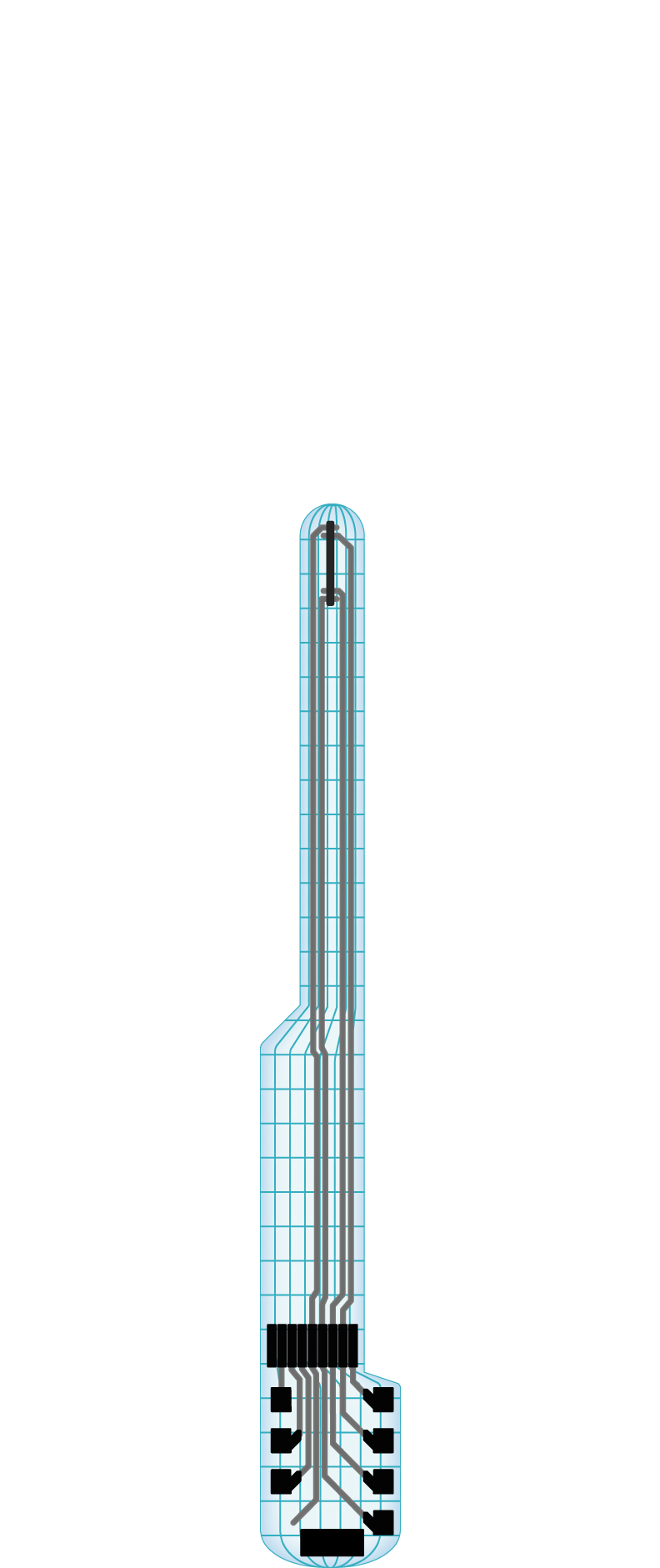

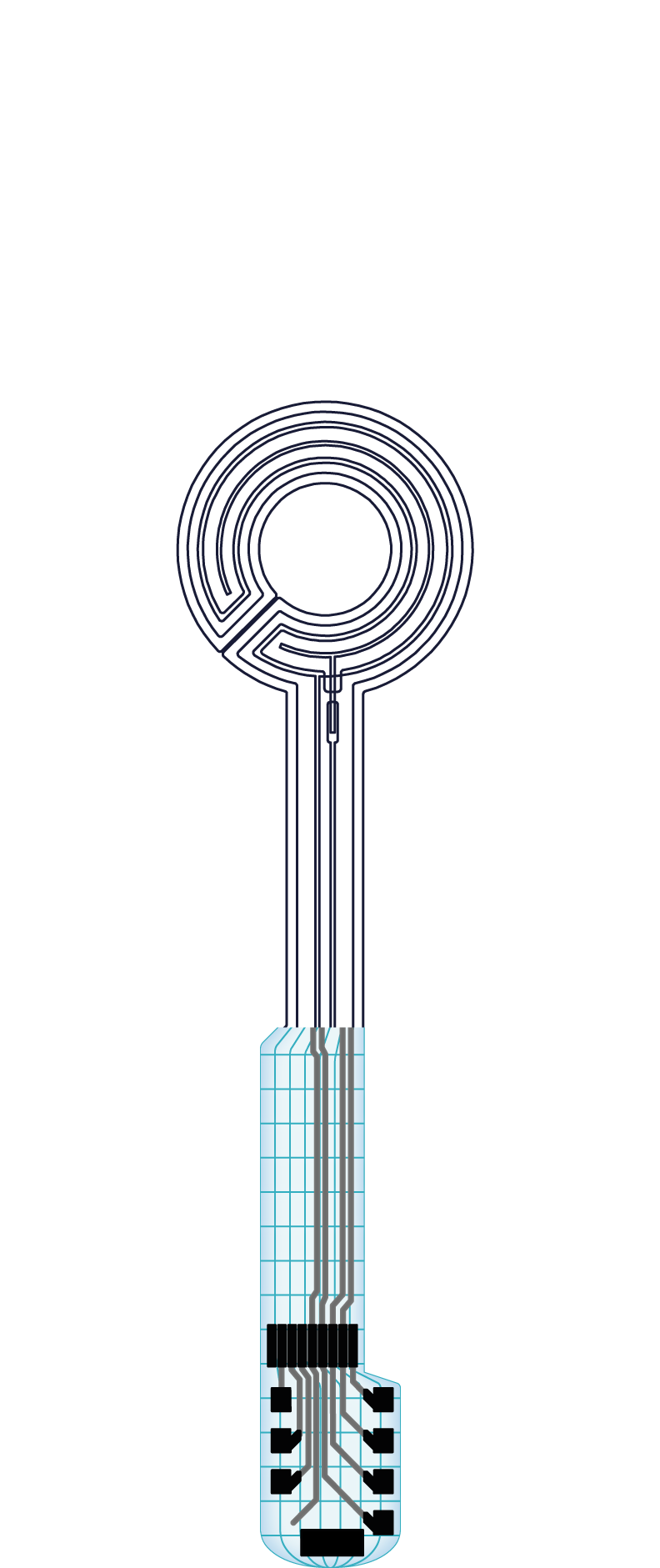

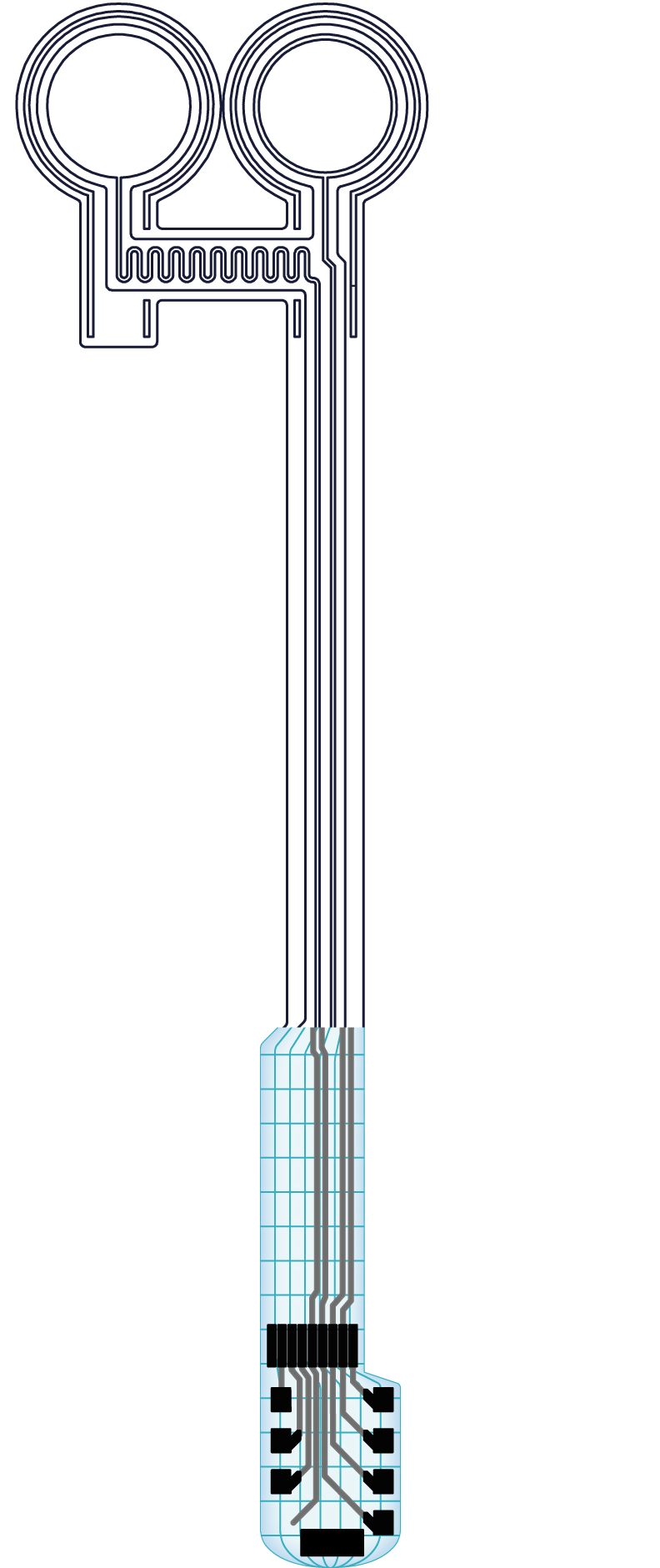

An der Spitze des Stripe befindet sich der Sensor, oder sogar mehrere Sensoren. An Ende des Stripe befinden sich die Kontaktierung.

Mit unseren Measurement Devices liefern wir direkt die passende Auswerteelektronik für unsere Stripe-Foliensensoren. Einfach den Stripe einstecken und los messen. Die Messdaten werden über Bluetooth LE an die accensors smartphone App oder an die accensors Lab App (Windows) übertragen.

Zudem liefern unsere handlichen und miniaturisierten Measurement Devices auch weitere Erkenntnisse, wie Raumtemperatur, Luftfeuchtigkeit, Luftdruck, Helligkeit und Bewegung.

Sie erhalten also einen umfangreichen Blick auf Ihre Messstelle durch denStripe-Foliensensor und die im Measurement integrierte Umfeldsensorik.

Schnelle Setup Time, begrenzte Messstabilität. Für Anwendungen mit schnell benötigten Messwerten und kurzen Messintervallen (Stunden).

Schnelle bis mittlere Setup Time, kurzzeitige bis mittlere Messstabilität. Für Anwendungen mit Messintervallen von Tagen.

Erweiterte Setup Time, längere Messstabilität. Für Anwendungen mit Messintervallen von mehreren Tagen bis Wochen.

Wir bieten Ihnen zwei Biosensoren Stripe Varianten (Dive-in & Drop-on) im 3-Elektroden Aufbau (frei wählbare Sensing-Elektrode, Referenz-Elektrode und Counter-Elektrode), passend für viele Standard-Potentiostaten

Das accensors Evaluation Device ist ein vielseitiges Messgerät, das mehr als nur Messelektronik bietet. Es ist speziell für die Verwendung mit Accensors Foliensensoren konzipiert und ermöglicht eine einfache und genaue Messung verschiedener physikalischer und elektrochemischer Parameter. Das Gerät verfügt über eine intuitive Benutzeroberfläche, die es dem Benutzer ermöglicht, schnell und einfach Messungen durchzuführen und Daten zu analysieren. Es kann sowohl mit einer Desktop-Software als auch App ausgelesen werden und wird für das Labor-Testing wie auch unter realen Einsatzbedingen im Feld verwendet.

Remote-fähig: Über ein Gateway (Bluetooth-Internet) können Sie Ihre Messdaten auch einfach in die Cloud senden und von Zuhause begutachten.

Sie suchen nach einer Sensorlösung, die perfekt auf Ihre speziellen Anforderungen zugeschnitten ist? Dann sind unsere Customized Sensoren genau das, wonach Sie suchen! Egal ob Sie eine eine spezielle Messgröße oder eine einzigartige Form benötigen – wir arbeiten eng mit Ihnen zusammen, um eine individuelle Sensorlösung zu entwickeln, die perfekt auf Ihre Bedürfnisse abgestimmt ist.

new kind of

sensors

We will contact you at regular intervals