An innovative, multimodal modular system consisting of sensors and intelligent evaluation electronics with integrated AI now enables faster and more efficient product realization, especially for the life science, medical technology and biotech markets.

The career of a developer is usually shaped at a young age. For birthdays or at Christmas, there are the first construction kits in which the first models of buildings or vehicles are playfully assembled.

Later in your career, you sit at your desk and are faced with the challenge of finding optimal solutions as quickly as possible for products with increasing complexity, which require several different sensor elements and energy self-sufficiency, especially for new applications such as in the Internet of Things (IoT).

This is where the partners accensors and GED Gesellschaft für Elektronik und Design come into play with their pioneering new developments. Together, they have combined the know-how gained from many years of collaboration with research institutes and their own experience to offer developers a modular solution that makes it much easier to integrate sensors and evaluation units with the appropriate power supply.

The idea: Similar to the manufacturers of the construction kits that shaped our childhood, accensors and GED rely on a multimodal modular system. This system consists of individual sensors as well as electronic and software modules that can be individually combined to create customized sensor systems and evaluation units. The result is a fast, cost-efficient solution to the challenges of sensor integration in Industry 4.0 applications for the development of cyber-physical systems (CPS) with a significantly faster “time to market”.

accensors SMD foilsensors: Innovative sensors, as simple as stickers

The sensory component of this system is the state-of-the-art SMD foilsensors from accensors. These sensors make it possible to carry out precise measurements by simply sticking them on like stickers. With a size of only 7.60 mm x 5.60 mm and an active measuring area of Ø2.5 mm, they offer remarkable performance in the smallest of spaces. These sensors are ready-to-use and can be easily attached to various contact points to measure a variety of parameters such as pH, temperature, chemical and bioelectrical parameters. Thanks to additively manufactured sensor technology, accensors enables easy mass production, which increases the availability and scalability of the sensors. The flexibility of these sensors also enables measurements away from rigid PCBs, which extends their applicability in various industries such as medical technology, biotechnology and the food industry.

GED SensorNode: Configurable sensor module system

With the SensorNode hardware and software kit, GED is adding the option of easily configuring a miniaturized, high-performance multi-sensor system. With plug-in modules no larger than a piece of sugar (16x18mm), the GED SensorNode is extremely compact and can be used even in the tightest of installation spaces. Thanks to the integrated Bluetooth radio, rechargeable battery and optional energy harvesting, no cables are required. In addition to the controller and energy module, further modules with MEMS sensors are available, such as gyro and acceleration sensors, acoustic and optical sensors, force and pressure sensors, which cover a wide range of highly integrated sensor functions. The latest module is the measurement module for amperometric-voltametric and impedance measurement, which is based on a highly integrated ASIC component. Modules with wire interfaces for I2C, USB and the new Single Pair Ethernet (SPE) are available for real-time transmission even in harsh environments. The modules can be plugged together as required and configure themselves automatically via Plug & Play.

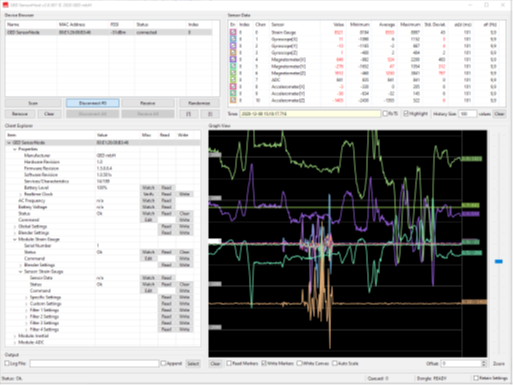

The associated third modular system for the software modules consists of the embedded software with configurability of the sensor front end via the wire or BLE interface. The “SN app” can be used to transmit multi-sensor values and alarms directly to the operator via smartphone or tablet. The SN host software, which runs on the PC, is used for local operation and data display. The embedded software of the SensorNode has powerful, programmable multi-sensor data pre-processing and special data filters that can be switched on. With these innovative functions, the amount of data in the network and on the servers can be significantly reduced. This also provides an optimal basis for multi-sensor applications for predictive maintenance.

“AI on the Edge” framework

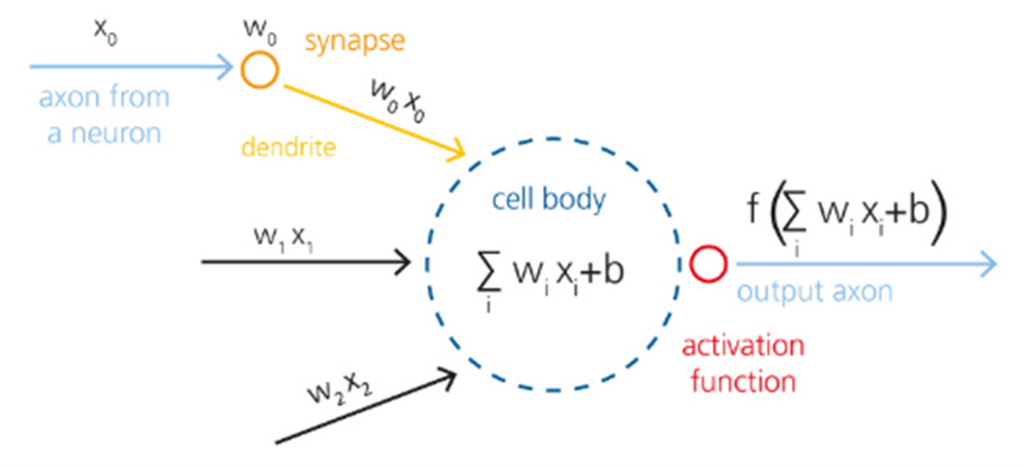

The fourth modular system module “AIfES” can be used to program functions for artificial intelligence and machine learning that run locally on the 32-bit SensorNode microcontroller. The basis is a feedforward neural network (FNN), which can be configured in almost all parameters and also enables deep network structures. The artificial neural network (ANN) is configured and calculated with only one main function. Regression and classification tasks are possible. The network structure can be adapted to the current technical task. AIfES stands for “Artificial Intelligence for Embedded Systems” and is an Ai framework from the Fraunhofer Institute for Microelectronic Circuits and Systems IMS and was jointly ported to the SensorNode microcontroller by IMS and GED as part of the BMBF research project KiNo.

Overview of the Ki:

- Number of inputs and outputs are freely definable

- Number of hidden layers and neurons per layer are freely definable.

- Different activation functions with additional parameters. Sigmoid, Softsign, ReLU, PReLU, Softmax

The partnership between accensors and GED now enables developers to configure high-precision sensors and innovative measurement, evaluation and data transfer electronics quickly and cost-effectively. GED offers support in adapting the SensorNode to customer-specific requirements. This modular system opens up an exciting future for sensor implementation, merging creativity and technology. The idea of toy kits is now combined with the technology to realize a world of smarter, sensor-based products in the shortest possible time.