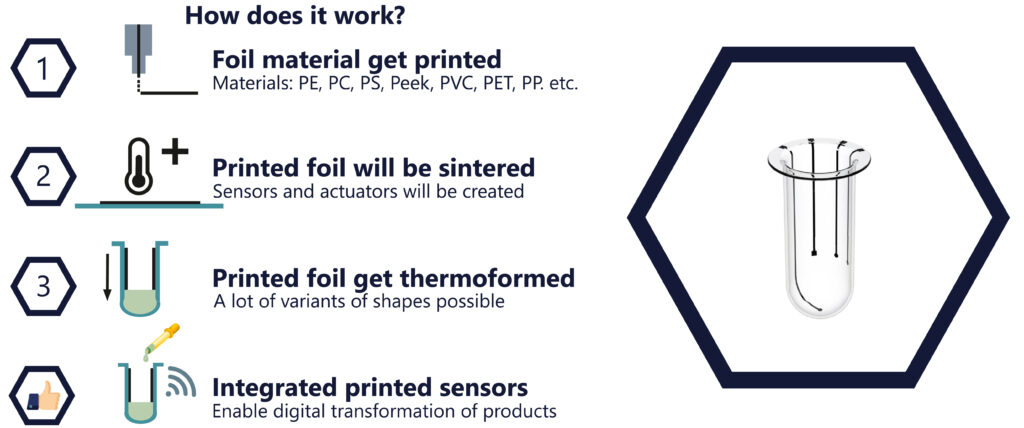

Printed electronics are very popular. While it is easy to apply conductive structures to a substrate, that alone does not make a sensor. At accensors, we manufacture foil sensors by combining different materials and elements. To do this, we use printing processes, dispensing processes, pick and play, and other additive or ablative processing methods. An example of this is multilayer construction, in which different materials are built up one on top of the other. The sensory properties of a multilayer structure can result from mechanical influences on the structure (e.g. in the case of a capacitive pressure sensor), changes in physical properties (e.g. changes in resistance in the case of a temperature sensor) or electrochemical effects that occur at a particularly sensitive electrode.

This is our core know-how at accensors: sensor functionalization.

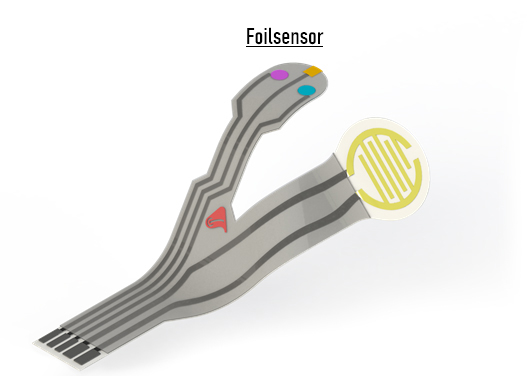

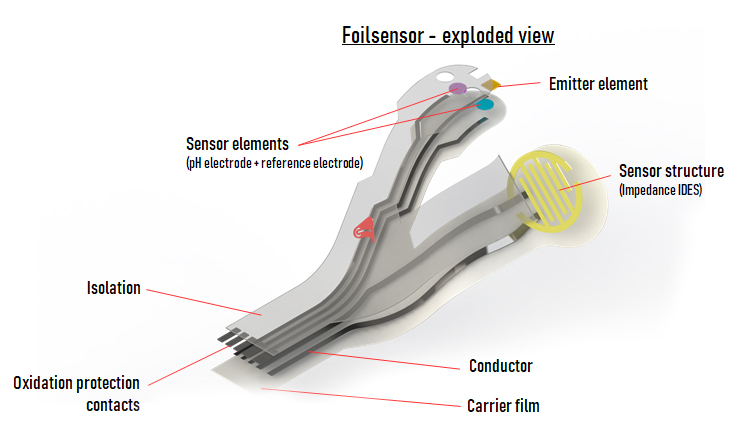

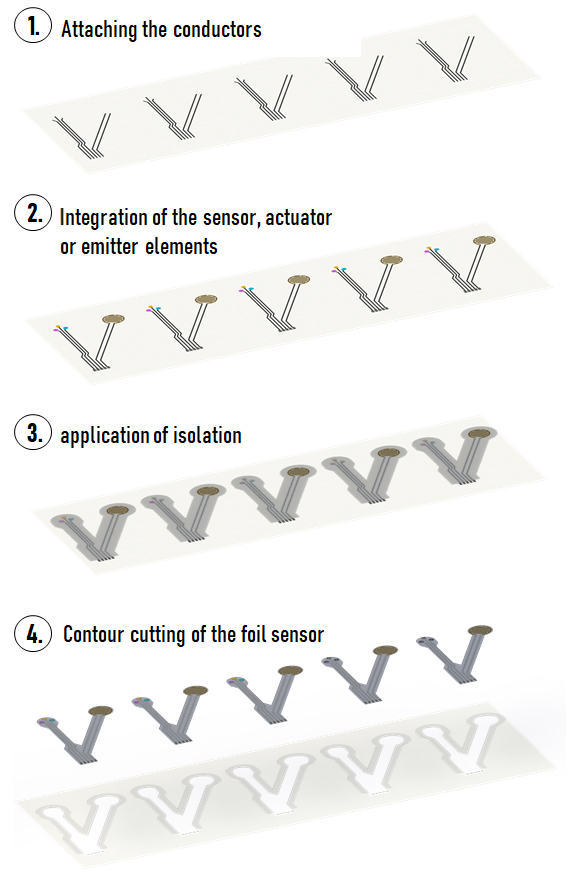

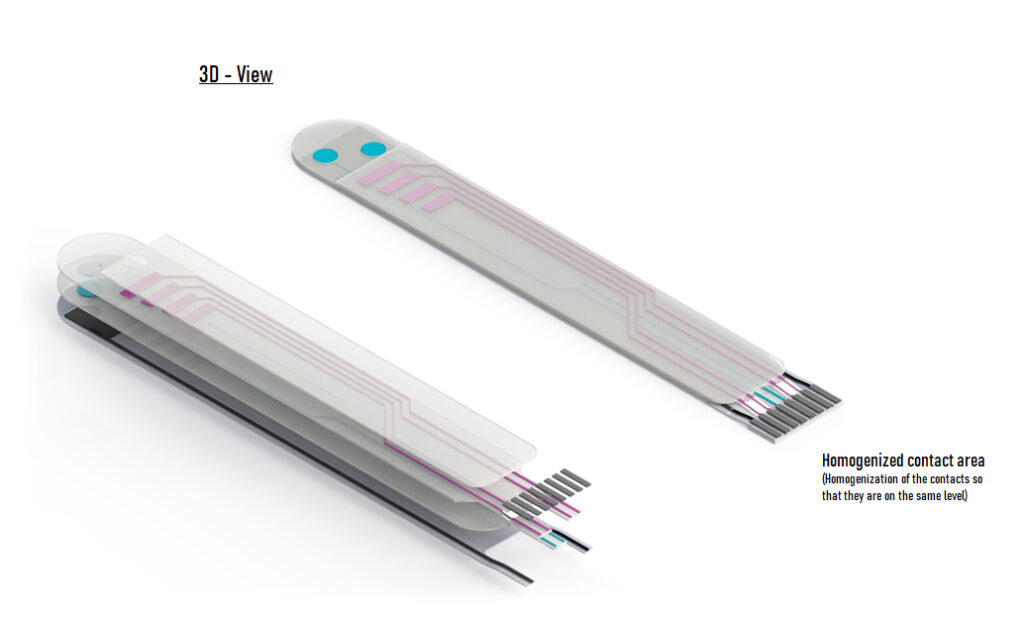

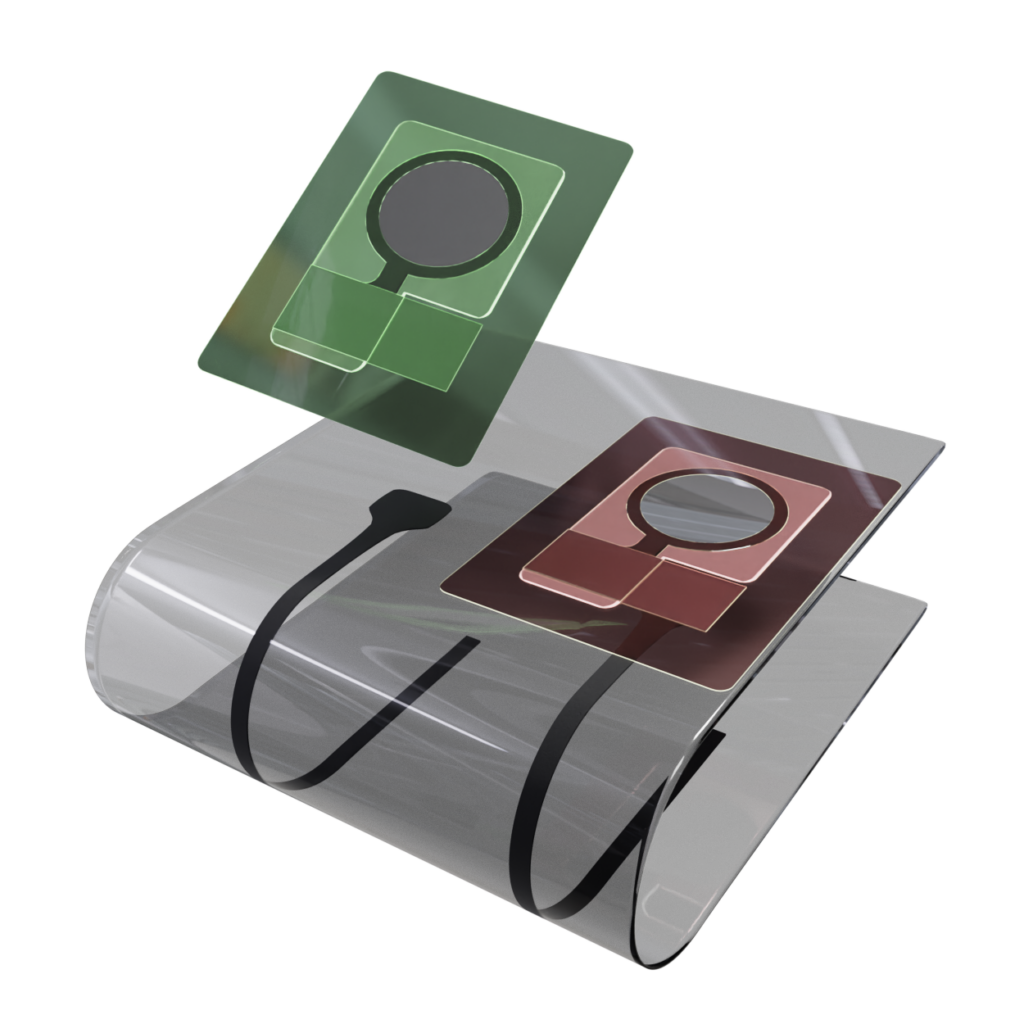

A foil sensor is an electrical functional element that is built on a flexible foil substrate. The substrate is usually made of plastic material and the functional element is built up in an additive process. A functional element comprises at least the electrical leads as well as the sensor element, the actuator element or the emitter element.

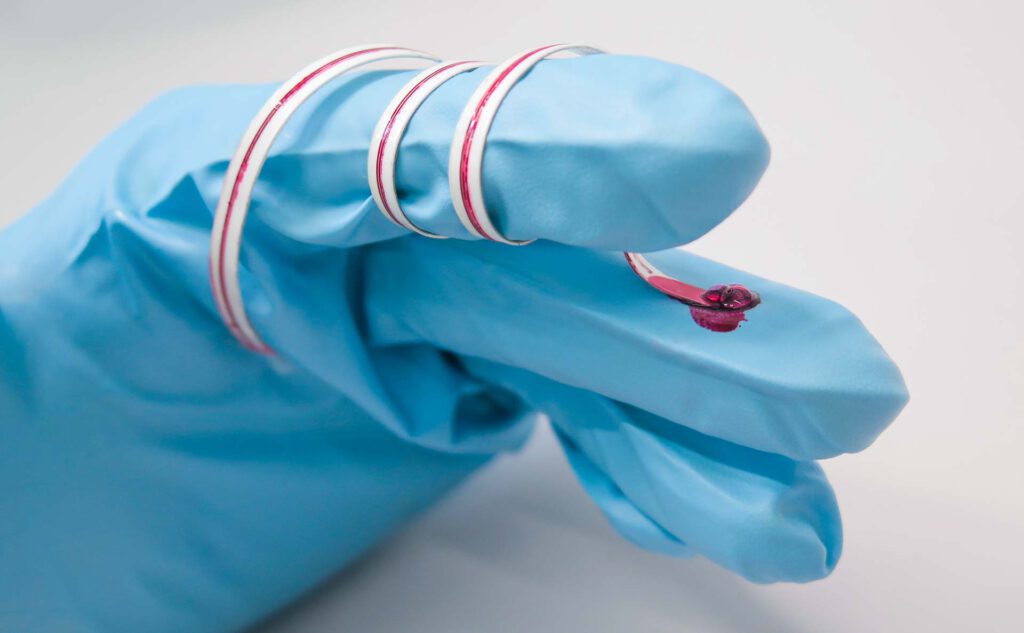

The foil design can be freely selected and the substrate can assume any contour. The layout determines the course of the electrical leads as well as the position and size of the sensor element, actuator element or emitter element on the contour foil substrate.

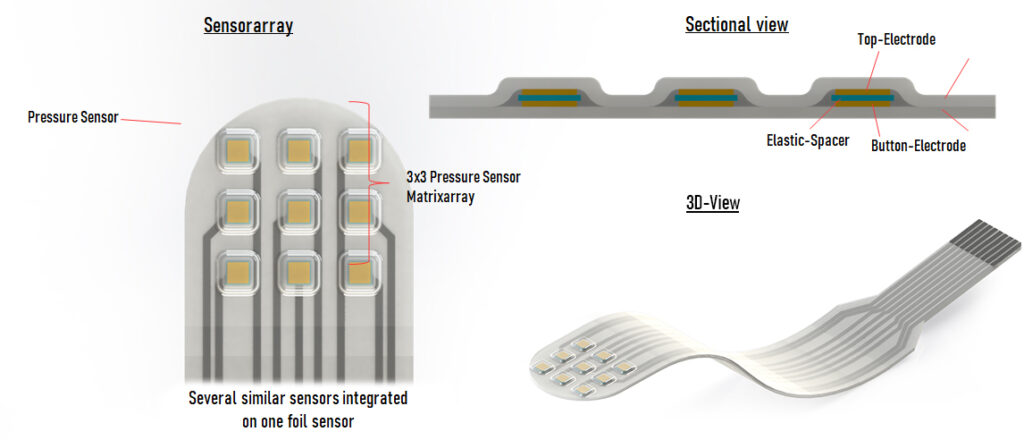

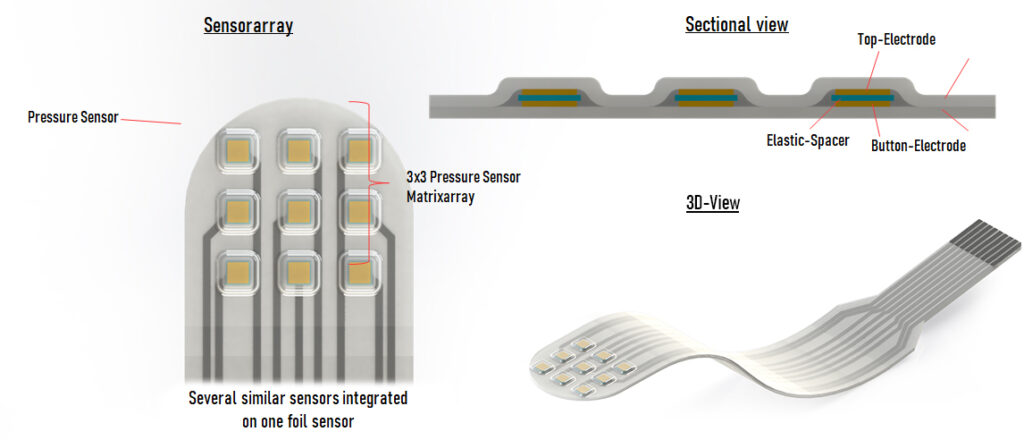

A sensor array is a way of integrating several identical sensors on a film substrate. In contrast to the multiparametric sensor, several identical sensors are applied here. These can be arranged evenly or without a recognizable pattern on the foil. The great advantage of this technology is a finer and more local detection of differences in the measured variable at different local points.

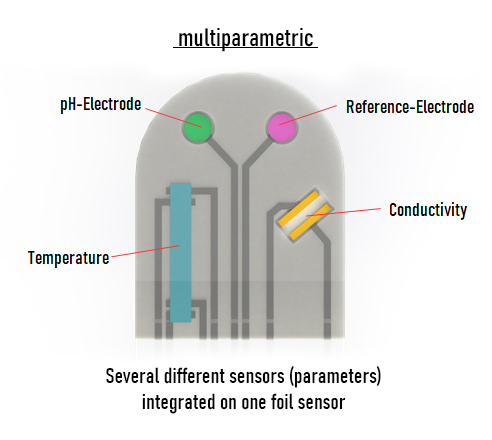

A multiparametric foil sensor is when several individual sensors are mounted on a foil sensor, which together can detect several different parameters (multiparameters).

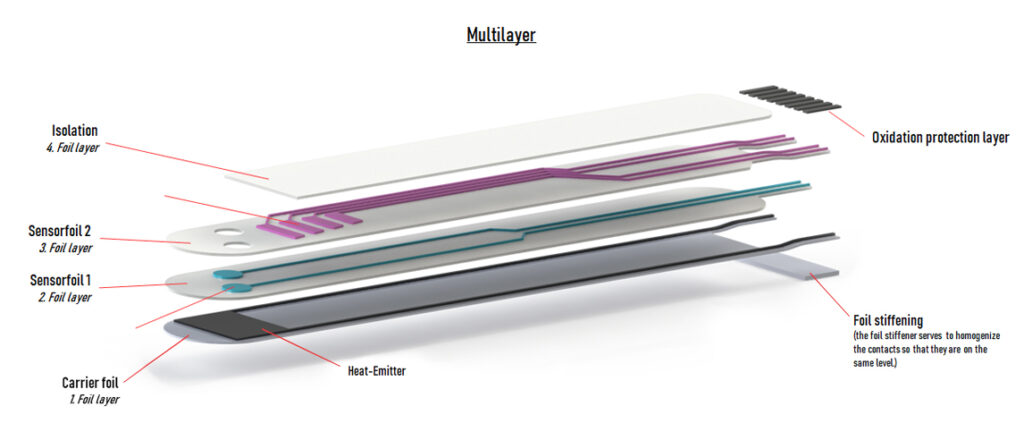

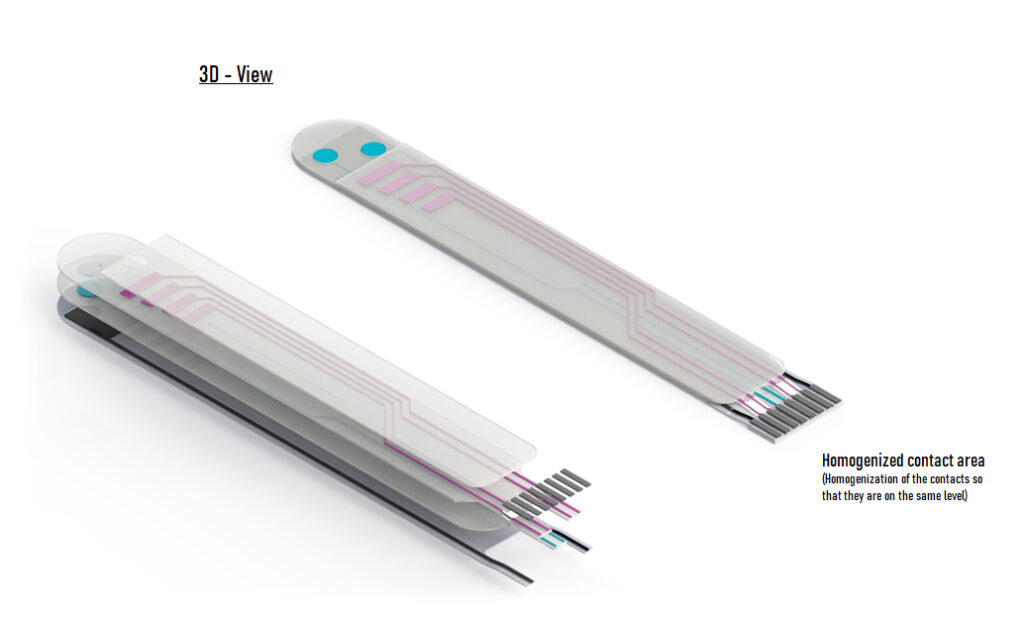

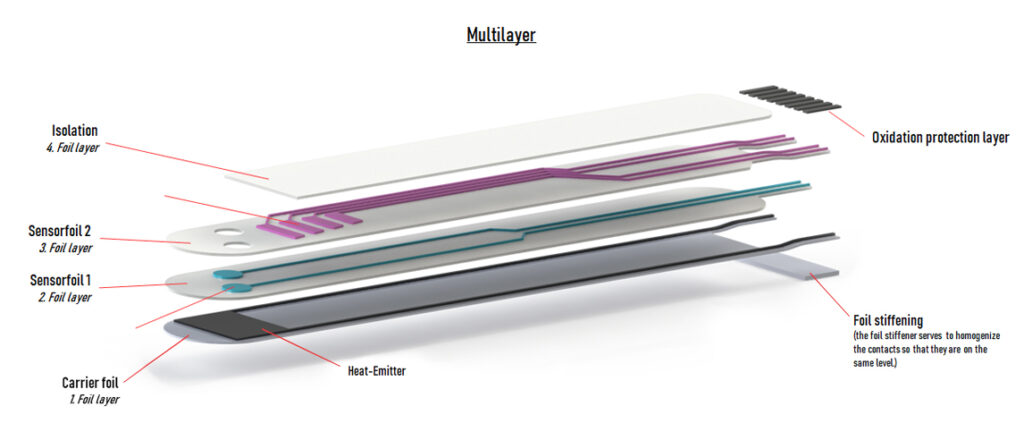

In multilayering, multiple foil substrates are built on top of each other to integrate multiple functions on top of each other instead of side by side. For example, in a polymerase chain reaction (PCR), a multilayer foil sensor is used where a heat emitter on the first foil layer performs the denaturation. The capture electrodes are placed directly above the hot layer on the second foil layer, but separated by a foil layer. A level sensor on the third foil layer completes this multilayer foil sensor.

Beim Multilagen werden mehrere Foliensubstrate übereinander aufgebaut, um mehrere Funktionen übereinander anstelle nebeneinander zu integrieren. Bei einer Polymerase-Kettenreaktion (PCR) wird beispielsweise ein Multilagen-Foliensensor eingesetzt, bei dem ein Heat-Emitter auf dem ersten Folienlayer die Denaturierung durchführt. Die Fängerelektroden sind direkt oberhalb der Heißschicht auf dem zweiten Folienlayer platziert, aber durch eine Folienschicht getrennt. Ein Levelsensor auf dem dritten Folienlayer vervollständigt diesen Multilagen-Foliensensor.

A sensor array is a way of integrating several identical sensors on a film substrate. In contrast to the multiparametric sensor, several identical sensors are applied here. These can be arranged evenly or without a recognizable pattern on the foil. The great advantage of this technology is a finer and more local detection of differences in the measured variable at different local points.

Foil sensors not only enable the integration of sensors, actuators and emitters on a flexible foil substrate, but also the direct integration of fluidic channels. This allows fluids to be sampled or media to be dispensed to specific points.

We offer two possibilities to realize microfluidic channels in or on a foil sensor.

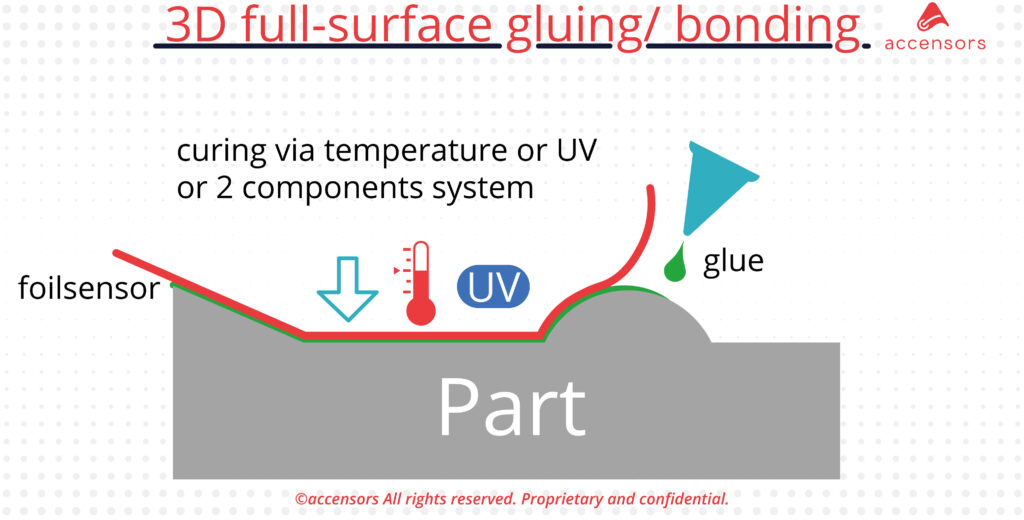

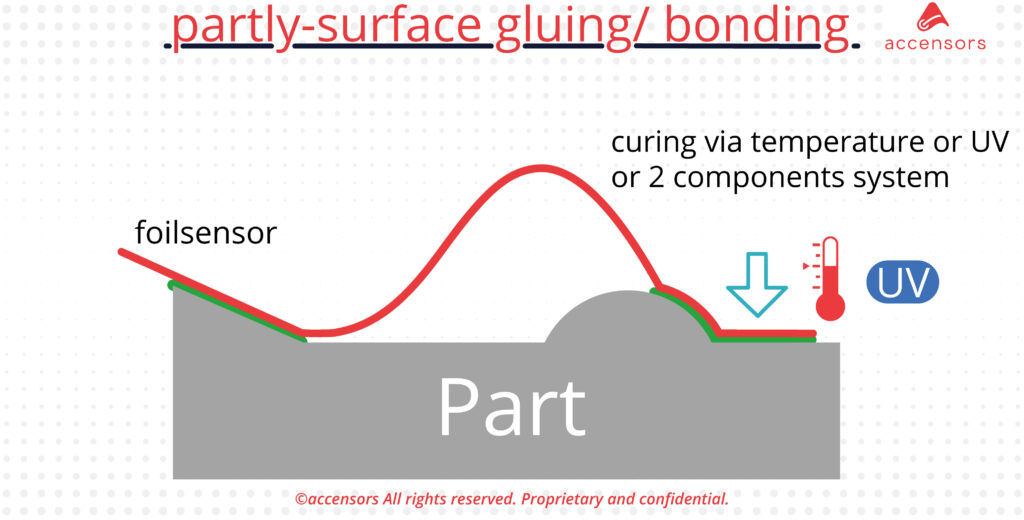

Adhesion is the process of creating a bond between the foil sensor and the component. An adhesion promoter is used to create adhesion. A solid adhesive requires contact pressure, while liquid adhesives cure by means of temperature, UV light or chemical activation. Unlike lamination, a foil sensor can also be applied to three-dimensional component surfaces. Transparent/optical adhesive systems allow visual inspection by the foil sensor.

Beim Laminieren werden Foliensensoren und Bauteile miteinander verbunden. Es gibt Heiß- und Kalt-Laminierung. Bei der Kalt-Laminierung werden Foliensensor, Bauteil und Haftvermittler unter Druck zusammengepresst. Bei der Heiß-Laminierung wird zusätzlich eine Temperatur zum Aktivieren des Haftvermittlers verwendet. Kalt-Laminierung ist einfach, aber weniger haftfest und nicht wärmestabil. Heiß-Laminierung bietet höhere Haftfestigkeit und Stabilität, erfordert aber höhere Anpressdrücke und Temperaturen.

Two methods are distinguished in assembling. Sandwich assembling fixes the foil sensor between two elements, while eyelet assembling involves attaching special eyelets to the foil material. Both methods allow foil sensors to be easily integrated into existing systems. Assembly is particularly suitable for integrating foil sensors at a later date.

Welding creates a stable, inseparable connection between the foil sensor and the component. The welding area must be large enough and outside of sensor and lead areas to avoid damage to the sensor. There are various welding methods such as ultrasonic, laser, heat pulse, convection, resistance or induction welding. Welding is the most sustainable integration principle, as no further foreign materials are introduced and it is particularly uncritical for measurement media such as blood or drinking water.

new kind of

sensors

We will contact you at regular intervals